Vimal Industrial Corporation is a leading supplier of DIN 1587 Hexagon Domed Cap Nuts based in Mumbai, India. Also known as acorn nuts or dome nuts, these precision‑engineered fasteners are designed to provide both functional thread protection and an aesthetically pleasing finish. We supply a wide range of sizes, materials, and finishes to meet the requirements of industries such as automotive, furniture, construction, marine, and general engineering.

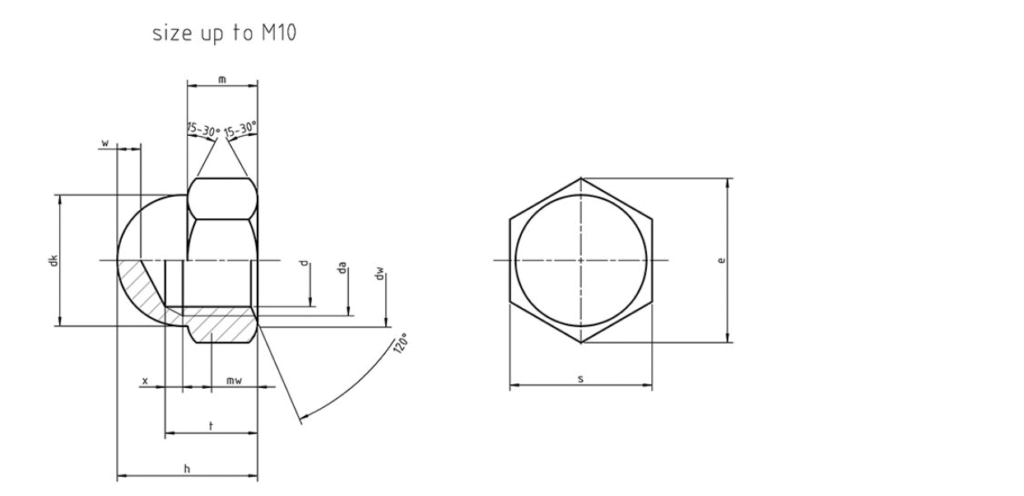

Manufactured as per DIN 1587 standards, these nuts feature a hexagonal base with a smooth, rounded dome that completely encloses exposed bolt threads. This design ensures protection against damage, corrosion, and injury, while enhancing the visual appeal of exposed fasteners in both structural and decorative applications. Whether used indoors or outdoors, DIN 1587 nuts offer a clean finish while maintaining structural integrity.

The demand for DIN 1587 Hexagon Domed Cap Nuts continues to grow across safety‑critical and design‑oriented applications. These nuts are widely preferred for their dual benefits — mechanical protection and decorative appeal. By covering the sharp thread ends of bolts or screws, they prevent injuries and damage to surrounding components, while also improving corrosion resistance by shielding the threads from environmental exposure.

At Vimal Industrial Corporation, we stock DIN 1587 nuts in stainless steel (A2/A4), brass, and carbon steel with various protective coatings, sourced from trusted manufacturers including APL Fasteners. All products meet strict dimensional and mechanical standards, ensuring performance consistency across different applications. With our large inventory, technical expertise, and reliable delivery network, we cater to both bulk industrial requirements and specialized project needs.

DIN 1587 nuts are used in industries where safety, durability, and appearance are important. Their enclosed dome design ensures thread protection and improved corrosion resistance, making them ideal for:

Automotive and Motorcycle – wheel assemblies, engine components, and exposed bolt ends

Furniture and Interior Design – decorative fastening and child‑safe assemblies

Architecture and Construction – railings, balustrades, and facade fittings

Marine and Offshore – corrosion‑resistant fastening for harsh environments

Food and Medical Equipment – hygienic fasteners for contamination‑free environments

General Engineering – any application where exposed threads need protection

As one of the most trusted fastener suppliers in India, Vimal Industrial Corporation is known for its commitment to quality, reliability, and customer satisfaction. Our DIN 1587 domed cap nuts are sourced from certified manufacturers, tested for quality, and delivered with complete traceability.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – Assured authenticity and quality compliance

✅ Wide Range in Stock – Sizes, materials, and finishes to suit all applications

✅ Bulk Order Capability – Efficient handling of large‑volume projects

✅ Technical Support – Guidance on selecting the right material and grade

✅ Fast Delivery Across India – From our strategically located Mumbai warehouse

✅ Quality Guarantee – Products conform to DIN and ISO standards

Whether you need DIN 1587 nuts for OEM manufacturing, project construction, or retail distribution, we provide a seamless procurement experience with dependable service and competitive pricing.

| thread | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Series 1 | ||||||||||||

| Series 2 | - | - | - | M8x1 | M10x1 | M12x1.5 | (M14x1.5) | (M16x1.5) | (M18x1.5) | M20x2 | (M22x1.5) | M24x2 |

| Series 3 | - | - | - | - | M10x1.25 | M12x1.25 | - | - | (M18x2) | M20x1.5 | (M22x2) | - |

| P Series 1 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| da min. | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| da max. | 4.6 | 5.75 | 6.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.7 | 25.9 |

| dk max. | 6.5 | 7.9 | 9.5 | 12.5 | 15 | 17 | 20 | 23 | 26 | 28 | 33 | 34 |

| dw min. | 5.9 | 6.9 | 8.9 | 11.6 | 14.6 | 16.6 | 19.6 | 22.5 | 24.9 | 27.7 | 31.4 | 33.3 |

| e min. Product grade A | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.35 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 |

| e min. Product grade B | 7.5 | 8.63 | 10.89 | 14.2 | 17.59 | 19.85 | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 |

| x max. | 1.4 | 1.6 | 2 | 2.5 | 3 | 3 | - | - | - | - | - | - |

| g2 max. Series 1 | - | - | - | - | 6.4 | 7.3 | 7.3 | 9.3 | 9.3 | 9.3 | 9.3 | 10.7 |

| g2 max. Series 2 | - | - | - | - | 5.6 | 5.6 | 5.6 | 5.6 | 5.6 | 7.3 | 5.6 | 7.3 |

| g2 max. Series 3 | - | - | - | - | 4.9 | - | - | - | 7.3 | 5.6 | 7.3 | - |

| h max. nominal size | 8 | 10 | 12 | 15 | 18 | 22 | 25 | 28 | 32 | 34 | 39 | 42 |

| dw min. P. grade A | 7.64 | 9.64 | 11.57 | 14.57 | 17.57 | 21.48 | 24.48 | 27.48 | 32.38 | 33.38 | 38.38 | 41.38 |

| e min. P. grade B | 7.42 | 9.42 | 11.3 | 14.3 | 17.3 | 21.16 | 24.16 | 27.16 | 31 | 33 | 38 | 41 |

| m max. | 3.2 | 4 | 5 | 6.5 | 8 | 10 | 11 | 13 | 15 | 16 | 18 | 19 |

| x max. Mw min. | 2.9 | 3.7 | 4.7 | 6.14 | 7.64 | 9.64 | 10.3 | 12.3 | 14.3 | 14.9 | 16.9 | 17.7 |

| Mw min. | 2.32 | 2.96 | 3.76 | 4.91 | 6.11 | 7.71 | 8.24 | 9.84 | 11.44 | 11.92 | 13.52 | 14.16 |

| r approx. | 3.25 | 3.75 | 4.75 | 6.25 | 7.5 | 8.5 | 10 | 11.5 | 13 | 14 | 16.5 | 17 |

| s Max. = nominal size | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 |

| s min. P. grade A | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 |

| s min. P. grade B | 6.64 | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 |

| t w min. | 5.26 | 7.21 | 7.71 | 10.65 | 12.65 | 15.65 | 17.65 | 20.58 | 24.58 | 25.58 | 28.58 | 30.5 |

| t w max. | 5.74 | 7.79 | 8.29 | 11.35 | 13.35 | 16.35 | 18.35 | 21.42 | 25.42 | 26.42 | 29.42 | 31.5 |

| Weight kg/1000pcs min. | 2 | 2 | 2 | 2 | 3 | 4 | 5 | 4 | 5 | 5 | 5 | 6 |

| Weight kg/1000pcs max. | - | - | - | 4.66 | 11 | 20.1 | 28.3 | - | 54.3 | 95 | 104 | 216 |

DIN 1587 Hexagon Domed Cap Nuts are commonly used to provide a finished appearance to exposed bolt ends while protecting the threads from damage, dirt, and corrosion. They are widely used in automotive, construction, furniture, and machinery applications.

These nuts are manufactured from different materials, including stainless steel grades A2 (304) and A4 (316) for corrosion resistance, as well as various carbon and alloy steels for higher strength applications. The material choice depends on the mechanical strength and environmental conditions.

A2 stainless steel (304) offers excellent corrosion resistance for most indoor and outdoor applications, while A4 stainless steel (316) provides superior resistance against acids, chlorides, and marine environments, making it suitable for coastal and chemical industry applications.

DIN 1587 nuts come in different strength classes, such as 50, 70, and 80 for stainless steel, and 4.6, 8.8, 10.9, and 12.9 for carbon and alloy steel. The higher the class number, the greater the tensile strength and load capacity.

Selecting the right DIN 1587 nut depends on factors such as the required strength class, material grade, corrosion resistance needs, and the environment where the nut will be used. For example, A4 stainless steel is ideal for marine environments, while high-strength alloy steel is best for heavy mechanical loads.