Vimal Industrial Corporation is a leading stockist and supplier of DIN 7981 self-tapping screws based in Mumbai, India. Manufactured to comply with DIN 7981 (ISO 7049 equivalent) standards, these pan-head, cross-recessed self-tapping screws are engineered for direct fastening into thin sheet metals, plastics, and light alloys without the need for pre-tapped threads. With accurate dimensions, sharp thread geometry, and controlled surface finishes, they provide secure fastening, repeatable torque values, and long-term joint reliability across diverse applications.

Our extensive inventory covers multiple sizes, drive styles, point types, and coatings, making us a trusted source for OEMs, EPC contractors, panel builders, and MRO teams who require dependable fasteners that save time and reduce installation costs.

As India’s electronics, switchgear, appliance, and HVAC sectors continue to rely on sheet-metal assemblies, the demand for DIN 7981 self-tapping screws remains high. Vimal Industrial Corporation meets this requirement by partnering with leading manufacturers most notably APL Fasteners to maintain an extensive, ready-to-ship inventory.

From small-lot replenishment to bulk project consignments, every delivery is stored in climate-controlled conditions and verified against DIN 7981 dimensional tolerances. Customers receive lot-traceability, mill test certificates, and third-party inspection reports on request, ensuring screws meet stringent QA/QC protocols.

Leveraging our strategic Mumbai warehouse and pan-India logistics, we can dispatch orders the same day—whether for urgent breakdowns or scheduled EPC requirements.

DIN 7981 self-tapping screws are designed for direct installation into sheet metals, plastics, and composites, delivering secure fastening without pre-tapped holes.

Common Applications Include:

Electrical Panels & Switchgear – fastening covers, bus-bar supports, and control housings.

HVAC & Ducting Systems – securing sheet-metal ducts, plenums, and support brackets.

Appliances & Consumer Products – assembly of housings, frames, and plastic enclosures.

Automotive & Rail Interiors – fastening trim, brackets, and lightweight fixtures.

General Fabrication – kiosks, cabinets, and light sheet-metal structures.

Maintenance & Repair (MRO) – rapid fastening solution for workshop and field jobs.

As a trusted name in the industrial fasteners sector, Vimal Industrial Corporation is known for reliable sourcing, prompt supply, and technical guidance. We specialize in supplying DIN 7981 screws that meet international standards, catering to a broad spectrum of industries.

Why clients across India choose us:

✅ Authorized APL Fasteners Dealer – assured genuine product with documentation

✅ Comprehensive Stock – full size range, carbon steel & stainless variants, and finishes on hand

✅ Custom Packing & Bulk Fulfilment – kit sets, bar-coded bags, or palletised exports

✅ Technical Guidance – support on drive selection, torque values, and substrate suitability

✅ Pan-India Reach – rapid supply to metro hubs, industrial corridors, and remote sites

✅ Stringent QA – screws inspected to DIN 7981 dimensional limits with ISO certifications

✅ Customer-First Service – fast quotations, dedicated account managers, and export paperwork support

Whether you’re an OEM, contractor, or buyer, we simplify your procurement of DIN 7981 screws with timely service, accurate documentation, and consistent quality.

| Thread size | ST2,2 | ST2,9 | ST3,5 | (ST3,9) | ST4,2 | ST4,8 | ST5,5 | ST6,3 | |

|---|---|---|---|---|---|---|---|---|---|

| P | 0,8 | 1,1 | 1,3 | 1,3 | 1,4 | 1,6 | 1,8 | 1,8 | |

| a | max. | 0,8 | 1,1 | 1,3 | 1,3 | 1,4 | 1,6 | 1,8 | 1,8 |

| dk | nominal=max. | 4,2 | 5,6 | 6,9 | 7,5 | 8,2 | 9,5 | 10,8 | 12,5 |

| min. | 3,9 | 5,3 | 6,54 | 7,14 | 7,84 | 9,14 | 10,37 | 12,07 | |

| k | nominal=max. | 1,8 | 2,2 | 2,6 | 2,8 | 3,05 | 3,55 | 3,95 | 4,55 |

| min. | 1,55 | 1,95 | 2,35 | 2,55 | 2,75 | 3,25 | 3,65 | 4,25 | |

| r | max. | 0,3 | 0,4 | 0,5 | 0,5 | 0,6 | 0,7 | 0,8 | 0,9 |

| rf | approx. | 3,4 | 4,4 | 5,4 | 5,8 | 6,2 | 7,2 | 8,2 | 9,5 |

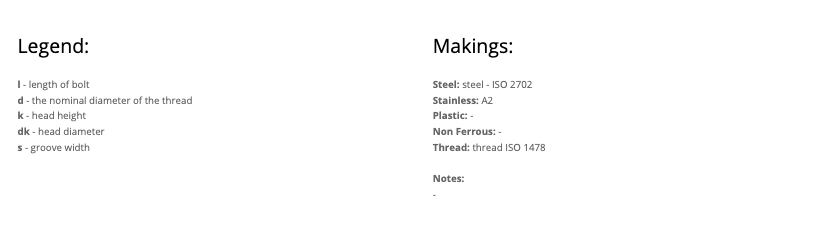

| Cross recess | No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 |

| Type H | m approx. | 2,6 | 3 | 4,2 | 4,4 | 4,6 | 5 | 6,5 | 7,1 |

| Penetration depth min. | 0,86 | 1,35 | 1,4 | 1,63 | 1,8 | 2,26 | 2,49 | 3 | |

| Penetration depth max. | 1,32 | 1,8 | 2,03 | 2,26 | 2,46 | 2,87 | 3,15 | 3,66 | |

| Type Z | m approx. | 2,4 | 2,9 | 3,9 | 4,1 | 4,3 | 4,7 | 6,2 | 6,7 |

| Penetration depth min. | 1,1 | 1,58 | 1,47 | 1,7 | 1,88 | 2,28 | 2,51 | 3,02 | |

| Penetration depth max. | 1,35 | 1,83 | 1,93 | 2,16 | 2,34 | 2,74 | 2,97 | 3,48 | |

| y | max. Type C | 2 | 2,6 | 3,2 | 3,5 | 3,7 | 4,3 | 5 | 6 |

| max. Type F | 1,6 | 2,1 | 2,5 | 2,7 | 2,8 | 3,2 | 3,6 | 3,6 | |

| l | Type C | Type F | Approximate mass (7,85 kg/dm³), per 1000 units in kg |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | nominal | |||||||||

| 4,5 | 3,7 | 5,3 | 3,7 | 4,5 | 0,174 | ||||||||

| 6,5 | 5,7 | 7,3 | 5,7 | 6,5 | 0,214 | 0,424 | |||||||

| 9,5 | 8,7 | 10,3 | 8,7 | 9,5 | 0,274 | 0,532 | 0,84 | 1,07 | 1,26 | 1,85 | |||

| 13 | 12,2 | 13,8 | 12,2 | 13 | 0,344 | 0,658 | 1,02 | 1,29 | 1,5 | 2,18 | 3,24 | 4,32 | |

| 16 | 15,2 | 16,8 | 15,2 | 16 | 0,404 | 0,766 | 1,17 | 1,48 | 1,71 | 2,46 | 3,62 | 4,86 | |

| 19 | 18,2 | 19,8 | 18,2 | 19 | 0,874 | 1,32 | 1,67 | 1,92 | 2,74 | 4 | 5,4 | ||

| 22 | 21,2 | 22,8 | 20,7 | 22 | 1,47 | 1,86 | 2,13 | 3,02 | 4,38 | 5,94 | |||

| 25 | 24,2 | 25,8 | 23,7 | 25 | 1,62 | 2,05 | 2,34 | 3,3 | 4,76 | 6,48 | |||

| 32 | 30,7 | 33,3 | 30,7 | 32 | 2,83 | 3,96 | 5,67 | 7,74 | |||||

| 38 | 36,7 | 39,3 | 36,7 | 38 | 4,52 | 6,45 | 8,82 | ||||||

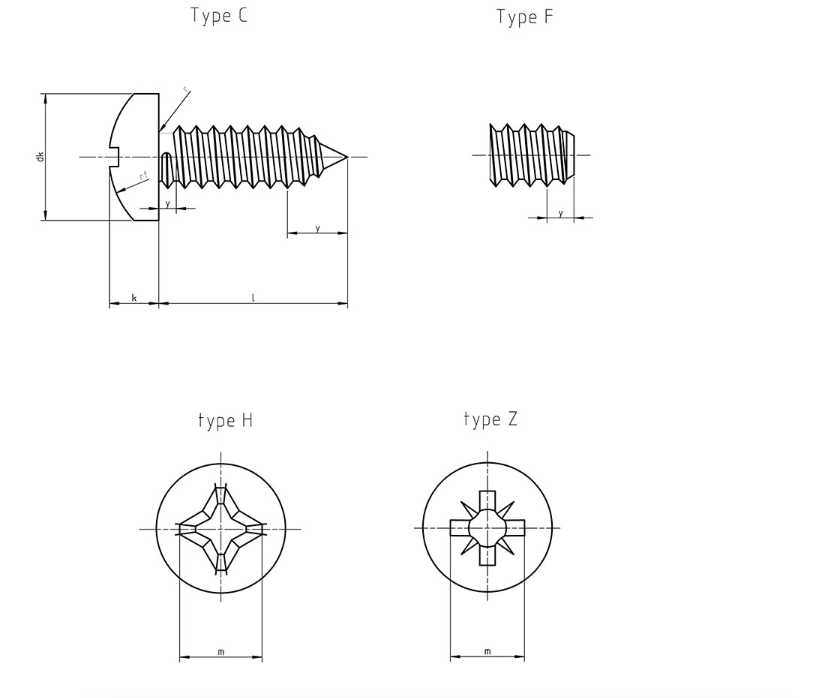

DIN 7981 defines cross-recessed pan head self-tapping screws with thread-forming “Type C” geometry. These screws cut their own mating threads into sheet metals, plastics, and light alloys, eliminating the need for pre-tapped holes.

DIN 7981 screws have a pan head with cross recess, while DIN 7982 screws feature a countersunk head. Both share self-tapping thread designs, but the head style determines whether the fastener sits flush (7982) or above the surface (7981).

They are usually manufactured from case-hardened carbon steel for general sheet-metal applications and stainless steel grades (A2, A4) where corrosion resistance is critical.

They are widely applied in electrical panels, HVAC systems, consumer appliances, automotive interiors, and general fabrication, wherever thin sheet materials require secure fastening without pre-tapping.

Typical finishes include zinc plating, nickel coating, black oxide, and plain/oiled, each selected according to environmental exposure, appearance, and torque-tension requirements.