Vimal Industrial Corporation is a trusted stockist and supplier of DIN 7982 precision self-tapping screws based in Mumbai, India. Manufactured to comply with DIN 7982 (ISO 7049 equivalent), these countersunk head, cross-recessed screws are designed for flush installation in sheet metals, plastics, and light alloys. They form their own mating threads, ensuring precise alignment, secure preload, and a clean surface finish ideal for assemblies where appearance and space-saving are critical.

With a wide range of sizes, materials, and protective finishes, we serve OEMs, panel builders, EPC contractors, and MRO teams requiring dependable fastening solutions that combine structural performance with aesthetic installation.

As industries increasingly demand flush-mount fastening for sheet assemblies, DIN 7982 screws remain an essential choice. Vimal Industrial Corporation ensures a ready-to-ship inventory by partnering with leading manufacturers such as APL Fasteners, covering the full range of diameters and lengths in both carbon steel and stainless steel variants. Every lot is packaged according to project requirements, whether in bar-coded cartons, kit assortments, or export-grade pallets, giving buyers flexibility in procurement and handling.

To maintain consistent quality, all screws are stored in controlled conditions and inspected to DIN 7982 tolerances. Customers also receive complete documentation including lot traceability, mill test certificates, and third-party inspection reports where required. Leveraging our strategic Mumbai warehouse and pan-India logistics network, we dispatch same-day shipments for EPC contractors, OEMs, and urgent repair projects, minimizing downtime and ensuring dependable project execution.

DIN 7982 screws are chosen when flush fastening and smooth finishes are required in sheet-metal and plastic assemblies.

Common Applications Include:

Electrical & Electronics – circuit boards, panels, and enclosures requiring flush-mounted screws.

HVAC & Ducting Systems – countersunk fittings on ducts, housings, and access panels.

Appliances & Consumer Goods – clean-surface fastening in housings, casings, and covers.

Automotive Interiors – trim parts, dashboard assemblies, and mounting clips.

Sheet-Metal Fabrication – kiosks, cabinets, and precision fixtures where head protrusion is undesirable.

General MRO – retrofit or repair jobs requiring both strength and flush aesthetics.

Vimal Industrial Corporation stands out for its technical expertise, authentic sourcing, and timely supply in the industrial fasteners sector.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – guaranteed genuine supply with manufacturer documentation

✅ Comprehensive Stock – multiple diameters, lengths, and finishes always available

✅ Bulk & Custom Packing – project-based kits, cartons, or export-ready pallets

✅ Technical Support – guidance on drive types, torque settings, and sheet thickness suitability

✅ Pan-India Distribution – rapid supply to metro hubs and industrial zones

✅ Quality Certifications – dimensional checks, mechanical test reports, and ISO-compliant documentation

✅ Customer-First Approach – quick quotations, dedicated account managers, and export facilitation

For OEMs, contractors, and industrial buyers, we simplify procurement of DIN 7982 countersunk self-tapping screws with consistent quality and dependable service.

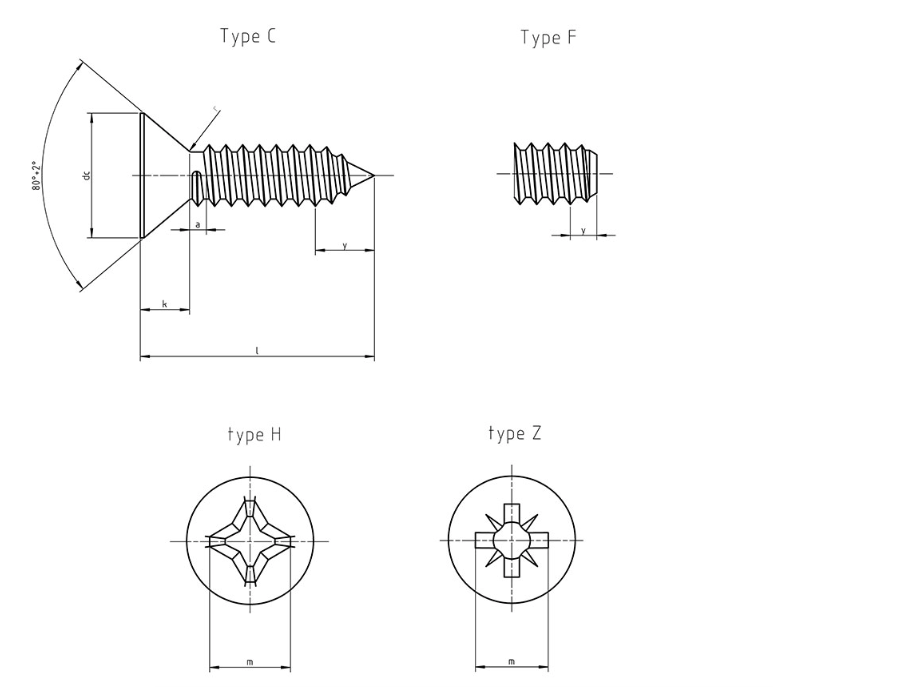

| Thread size | ST2,2 | ST2,9 | ST3,5 | (ST3,9) | ST4,2 | ST4,8 | ST5,5 | ST6,3 | |

|---|---|---|---|---|---|---|---|---|---|

| P | 0,8 | 1,1 | 1,3 | 1,3 | 1,4 | 1,6 | 1,8 | 1,8 | |

| a | max. | 0,8 | 1,1 | 1,3 | 1,3 | 1,4 | 1,6 | 1,8 | 1,8 |

| dk | nominal=max. | 4,3 | 5,5 | 6,8 | 7,5 | 8,1 | 9,5 | 10,8 | 12,4 |

| min. | 4 | 5,2 | 6,44 | 7,14 | 7,74 | 9,14 | 10,37 | 11,97 | |

| k | approx. | 1,3 | 1,7 | 2,1 | 2,3 | 2,5 | 3 | 3,4 | 3,8 |

| r | max. | 0,8 | 1,1 | 1,4 | 1,5 | 1,6 | 1,9 | 2,1 | 2,4 |

| Cross recess | No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 |

| Type H | m approx. | 2,5 | 3 | 4,2 | 4,6 | 4,7 | 5,1 | 6,8 | 7,1 |

| Penetration depth min. | 1,02 | 1,4 | 1,62 | 2,03 | 2,11 | 2,59 | 2,95 | 3,33 | |

| max. | 1,32 | 1,7 | 2,12 | 2,53 | 2,62 | 3,1 | 3,53 | 3,91 | |

| Type Z | m approx. | 2,4 | 2,9 | 3,9 | 4,1 | 4,3 | 4,7 | 6,2 | 6,7 |

| Penetration depth min. | 1,1 | 1,48 | 1,6 | 1,85 | 2,05 | 2,64 | 2,72 | 3,38 | |

| max. | 1,35 | 1,73 | 2,06 | 2,31 | 2,51 | 3,1 | 3,18 | 3,84 | |

| y | max. Type C | 2 | 2,6 | 3,2 | 3,5 | 3,7 | 4,3 | 5 | 6 |

| Type F | 1,6 | 2,1 | 2,5 | 2,7 | 2,8 | 3,2 | 3,6 | 3,6 | |

| L nominal |

Type C | Type F | Weight kg / 1000 pcs | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | ||||||||||

| 4,5 | 3,7 | 5,3 | 3,7 | 4,5 | 0,174 | ||||||||

| 6,5 | 5,7 | 7,3 | 5,7 | 6,5 | 0,214 | 0,424 | |||||||

| 9,5 | 8,7 | 10,3 | 8,7 | 9,5 | 0,274 | 0,532 | 0,84 | 1,07 | 1,26 | 1,85 | |||

| 13 | 12,2 | 13,8 | 12,2 | 13 | 0,344 | 0,658 | 1,02 | 1,29 | 1,5 | 2,18 | 3,24 | 4,32 | |

| 16 | 15,2 | 16,8 | 15,2 | 16 | 0,404 | 0,766 | 1,17 | 1,48 | 1,71 | 2,46 | 3,62 | 4,86 | |

| 19 | 18,2 | 19,8 | 18,2 | 19 | 0,874 | 1,32 | 1,67 | 1,92 | 2,74 | 4 | 5,4 | ||

| 22 | 21,2 | 22,8 | 20,7 | 22 | 1,47 | 1,86 | 2,13 | 3,02 | 4,38 | 5,94 | |||

| 25 | 24,2 | 25,8 | 23,7 | 25 | 1,62 | 2,05 | 2,34 | 3,3 | 4,76 | 6,48 | |||

| 32 | 30,7 | 33,3 | 30,7 | 32 | 2,83 | 3,96 | 5,67 | 7,74 | |||||

| 38 | 36,7 | 39,3 | 36,7 | 38 | 4,52 | 6,45 | 8,82 | ||||||

DIN 7982 defines countersunk head, cross-recessed self-tapping screws with Type C thread-forming geometry. These screws cut their own mating threads into sheet metals and plastics, enabling flush fastening without pre-tapped holes.

DIN 7982 screws have a countersunk head, which sits flush with the surface after installation, making them suitable for applications where a smooth finish is required. DIN 7981 screws, by contrast, have a pan head that remains above the surface.

They are generally made from case-hardened carbon steel for standard sheet-metal use, and stainless steel grades (A2, A4) where higher corrosion resistance or outdoor applications are required.

They are widely used in electrical and electronics assemblies, HVAC ducting, consumer appliances, sheet-metal fabrication, and automotive interiors where flush-mounted fastening is essential.

Common finishes include zinc plating, nickel coating, black oxide, and plain/oiled, each selected based on corrosion resistance, torque control, and aesthetic requirements.