Vimal Industrial Corporation is a leading stockist and supplier of DIN 914 socket set screws based in Mumbai, India. Manufactured as per DIN 914 standards, these screws feature an internal hex (Allen) drive with a cone-point tip, designed to penetrate the mating surface and provide exceptionally strong, vibration-resistant locking. DIN 914 cone-point set screws are ideal for applications where precise positioning, high holding force, and permanent or semi-permanent locking of components are required.

With a wide inventory across multiple thread sizes, lengths, property classes, and corrosion-resistant materials, we support OEMs, machine builders, automation companies, power-transmission manufacturers, and MRO teams that rely on high-integrity fastening for critical rotating and motion systems.

DIN 914 cone-point set screws are widely used where maximum bite and anti-slip locking are essential—particularly in shafts, hubs, collars, and couplings subjected to torque, impact, or vibration. As an authorized APL Fasteners dealer, Vimal Industrial Corporation maintains ready stock of DIN 914 screws from M3 to M24, typically in high-tensile alloy steel (45H / 12.9) and stainless steel (A2 / A4) for aggressive environments.

Each screw is manufactured and inspected to DIN 914 requirements for cone angle, point length, thread tolerance, hardness, and socket depth. All products are stored in controlled warehouse conditions and are supplied with mill test certificates, mechanical and chemical test reports, lot traceability, and third-party inspection on request. From our Mumbai warehouse, we service customers across India with both urgent breakdown dispatches and scheduled project supplies.

DIN 914 cone-point screws are used wherever deep, positive engagement and high resistance to slippage are required:

Shaft–Hub Connections – fixing pulleys, gears, sprockets, and collars to shafts

Power Transmission & Drives – couplings, clamping elements, and drive assemblies under dynamic loads

Automation & Motion Systems – locking cams, levers, pivot points, and actuator components

Heavy Machinery & Equipment – securing critical parts in pumps, compressors, presses, and gearboxes

Fixtures, Jigs & Tooling – robust locating and locking of adjustable stops and components

General Engineering & MRO – retrofit and repair jobs where set screws must not loosen in service

Vimal Industrial Corporation is trusted across India for standard-compliant products, consistent availability, and technical reliability.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – genuine DIN 914 cone-point set screws with full documentation

✅ Comprehensive Stock Range – wide selection of diameters, lengths, and strength classes ex-stock

✅ Material Options – high-tensile alloy steel and stainless steel for demanding environments

✅ Custom Packing & Kitting – project-wise kits, bar-coded cartons, or export-grade pallets

✅ Technical Support – guidance on point type selection (flat / cone / cup), torque, and seating practices

✅ Pan-India Logistics – fast dispatch from Mumbai to industrial hubs and remote project sites

✅ Quality Assurance – dimensional checks, hardness testing, and complete lot traceability

Whether you are working on new equipment, retrofit projects, or critical maintenance, we make sourcing DIN 914 socket set screws straightforward, traceable, and dependable.

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | |

| df | approx. | Lower limit of minor thread diameter | |||||||||||||

| dp | 0.7 | 0.8 | 1 | 1.5 | 2 | 2.5 | 3.5 | 4 | 5.5 | 7 | 8.5 | 12 | 15 | 18 | |

| min. | 0.45 | 0.55 | 0.75 | 1.25 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 5.2 | 6.64 | 11.57 | 14.57 | 17.57 | |

| e | min. | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 13.72 |

| Nom. | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | |

| s | min. | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 |

| max. | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.08 | 4.095 | 5.095 | 6.095 | 8.115 | 10.115 | 12.142 | |

| t | min. | 0.6 | 0.7 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | 3 | 4 | 4.8 | 6.4 | 8 | 10 |

| min. | 1.4 | 1.5 | 1.7 | 2 | 2 | 2.5 | 3 | 3 | 5 | 6 | 8 | 10 | 12 | 15 | |

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.3 | 1.5 | 1.8 | 2 | 2.5 | 3 | |

| l | Weight (7.85kg/dm3) kg/1000pcs | ||||||||||||||

| Nominal | min. | max. | |||||||||||||

| 2.5 | 2.3 | 2.7 | 0.018 | 0.023 | |||||||||||

| 3 | 2.8 | 3.2 | 0.022 | 0.029 | 0.044 | ||||||||||

| 4 | 3.76 | 4.24 | 0.029 | 0.037 | 0.059 | 0.1 | 0.13 | ||||||||

| 5 | 4.76 | 5.24 | 0.036 | 0.046 | 0.074 | 0.125 | 0.17 | 0.26 | |||||||

| 6 | 5.76 | 6.24 | 0.049 | 0.056 | 0.089 | 0.15 | 0.21 | 0.34 | 0.49 | ||||||

| 8 | 7.71 | 8.29 | 0.119 | 0.199 | 0.3 | 0.49 | 0.73 | 1.04 | |||||||

| 10 | 9.71 | 10.29 | 0.148 | 0.249 | 0.39 | 0.64 | 0.97 | 1.39 | 2.35 | ||||||

| 12 | 11.65 | 12.35 | 0.48 | 0.79 | 1.21 | 1.74 | 2.98 | 4.42 | |||||||

| 16 | 15.65 | 16.35 | 0.66 | 1.09 | 1.69 | 2.44 | 4.24 | 6.42 | 8.9 | ||||||

| 20 | 19.58 | 20.42 | 0.84 | 1.39 | 2.17 | 3.14 | 5.5 | 8.4 | 11.7 | 20.1 | |||||

| 25 | 24.58 | 25.42 | 2.77 | 4.02 | 7.09 | 10.8 | 15.3 | 26.6 | 40.7 | ||||||

| 30 | 29.58 | 30.42 | 4.9 | 8.68 | 13.3 | 18.9 | 33.2 | 51 | 68.7 | ||||||

| 35 | 34.5 | 35.5 | 5.78 | 10.3 | 15.8 | 22.5 | 39.7 | 61.3 | 83.2 | ||||||

| 40 | 39.5 | 40.5 | 11.9 | 18.3 | 26.1 | 46.3 | 71.6 | 98.2 | |||||||

| 45 | 44.5 | 45.5 | 81.9 | 113 | |||||||||||

| 50 | 49.5 | 50.5 | 92.2 | 128 | |||||||||||

| 55 | 54.4 | 55.6 | 143 | ||||||||||||

| 60 | 59.4 | 60.6 | 158 | ||||||||||||

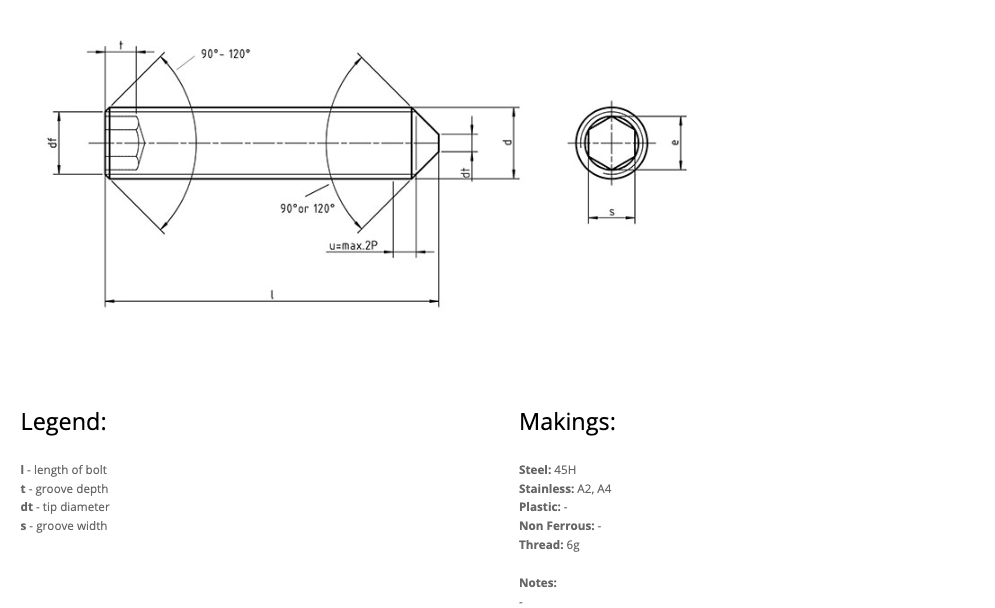

DIN 914 defines a headless socket set screw with an internal hex drive and a cone-point tip. The conical point penetrates the mating surface, providing very strong, slip-resistant locking for shafts, hubs, collars, and rotating parts.

DIN 913: flat point – non-marring, used for adjustments and where surface damage must be avoided.

DIN 914: cone point – sharp, penetrating tip for maximum holding force and positional security.

DIN 916: cup point – biting contact with strong grip, but less penetrating than cone point.

DIN 914 is typically chosen when the joint must not slip under high torque or vibration.

DIN 914 set screws are commonly manufactured in high-tensile alloy steel (e.g., 45H / class 12.9) for maximum strength, and in stainless steel grades A2 and A4 for corrosion-prone or outdoor applications. Surface finishes include black oxide, zinc plating, and plain/oiled, depending on the required protection and appearance.

They are widely used in power transmission assemblies, motors, gearboxes, automation mechanisms, shaft couplings, pulleys, sprockets, and heavy machinery, wherever a component must be locked securely onto a shaft or positioned without any rotational slip.

As an authorized APL Fasteners dealer in Mumbai, Vimal Industrial Corporation supplies DIN-compliant, fully traceable DIN 914 set screws with ready stock, fast pan-India delivery, test certificates, and technical guidance. This combination of availability, documentation, and expertise makes us a preferred sourcing partner for OEMs, EPC contractors, and MRO teams.