Vimal Industrial Corporation is a leading stockist and supplier of DIN 915 socket set screws based in Mumbai, India. Built according to DIN 915 standards, these screws feature an internal hex (Allen) drive with a dog-point tip, designed to provide precise axial positioning without damaging the mating surface. The extended cylindrical point ensures accurate engagement with a pre-drilled hole or slot, making DIN 915 screws ideal for applications where repeatable alignment, guided locking, or controlled linear positioning is required.

We maintain a comprehensive inventory of DIN 915 dog-point set screws in multiple diameters, lengths, and material grades—supporting OEMs, automation companies, machine builders, instrumentation manufacturers, and MRO teams that rely on precise, non-destructive fastening.

DIN 915 dog-point screws are widely used where components need to be positioned with accuracy, frequently adjusted, or guided along a predetermined slot. Vimal Industrial Corporation maintains ready stock from M3 to M24, available in hardened alloy steel (45H, 12.9) and stainless-steel grades A2/A4 for corrosive or hygiene-sensitive environments.

All products comply with DIN 915 dimensional and mechanical requirements, including point length, diameter tolerances, hardness, and socket depth. Our controlled warehouse ensures batch consistency, and every order can be supplied with mill test certificates, chemical/mechanical test reports, and lot traceability. With our Mumbai warehouse and strong pan-India logistics, we support urgent industrial maintenance and routine OEM production schedules alike.

DIN 915 screws are used where accurate, repeatable positioning and non-damaging engagement are required:

Precision Machinery & Automation – alignment of mechanical stops, guides, and levers

Instrumentation & Measuring Devices – repeatable positioning of sliders, detents, and mechanisms

Shaft & Hub Assemblies – locking into pre-drilled holes without scoring the shaft

Linear Motion Systems – guided movement along slots and adjustment rails

Fixtures, Jigs & Tooling – positioning stops and locating points that require frequent adjustment

General Engineering & MRO – applications requiring controlled seating without penetrating the mating surface

Vimal Industrial Corporation is trusted by industries across India for accuracy, reliability, and verified quality.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – assured genuine, standard-compliant dog-point set screws

✅ Extensive Stock Availability – all major thread sizes, lengths, and grades kept ready

✅ Material Flexibility – high-tensile alloy steel and stainless steel variants

✅ Custom Packing Options – project kits, bar-coded boxes, and export-grade pallets

✅ Technical Support – guidance on point-type selection (flat / cone / dog), torque, and application suitability

✅ Pan-India Delivery – quick dispatch from Mumbai to all major industrial regions

✅ Quality Assurance – dimensional checks, hardness tests, and batch traceability for every shipment

Whether for precision control systems, rotating equipment, or adjustable machinery, Vimal Industrial Corporation provides DIN 915 dog-point socket set screws with dependable performance and certified quality.

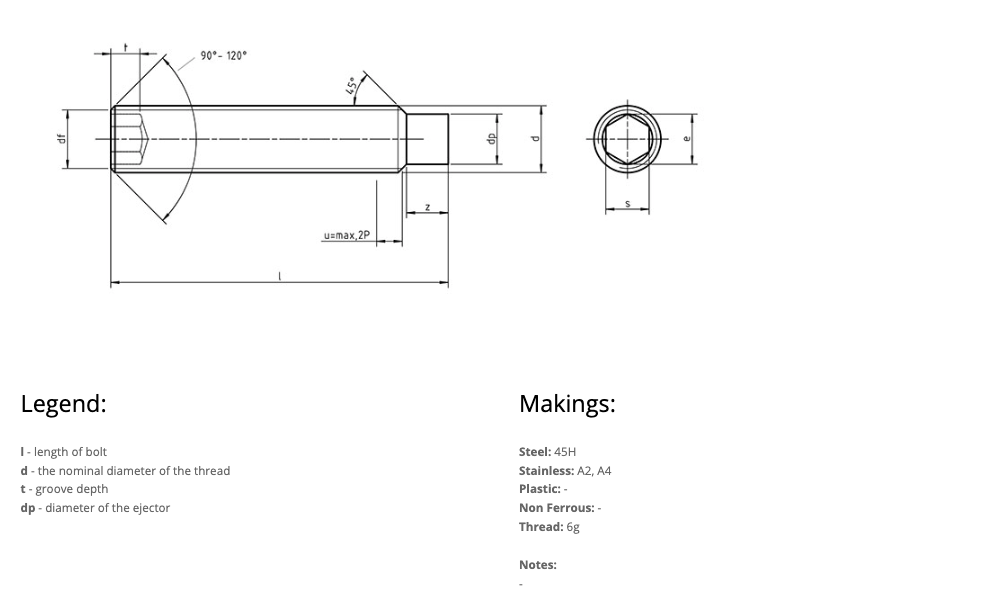

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 |

| df | approx. | Lower limit of minor thread diameter | ||||||||||||

| dp max. | 0.7 | 0.8 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5.5 | 7 | 8.5 | 12 | 15 | 18 |

| dp min. | 0.45 | 0.55 | 0.75 | 1.25 | 1.75 | 2.25 | 3.2 | 3.7 | 5.2 | 6.64 | 8.14 | 11.56 | 14.57 | 17.57 |

| e min. | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 13.72 |

| e Nom. | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| s min. | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 |

| s max. | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.08 | 4.095 | 5.095 | 6.095 | 8.115 | 10.115 | 12.142 |

| t min. | 0.6 | 0.7 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | 3 | 4 | 4.8 | 6.4 | 8 | 10 |

| t max. | 1.4 | 1.5 | 1.7 | 2 | 2 | 2.5 | 3 | 3.5 | 5 | 6 | 8 | 10 | 12 | 15 |

| z min. | 0.4 | 0.4 | 0.5 | 0.63 | 0.75 | 1 | 1.25 | 1.5 | 2 | 3 | 4 | 5 | 6 | |

| z max. | 0.65 | 0.65 | 0.65 | 0.88 | 1 | 1.25 | 1.5 | 1.75 | 2.25 | 2.75 | 3.25 | 4.3 | 5.3 | 6.3 |

| z min. | 0.8 | 0.8 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | 5 | 6 | 8 | 10 | 12 | |

| z max. | 1.05 | 0.724 | 1.25 | 1.5 | 1.75 | 2.25 | 2.75 | 3.25 | 4.3 | 5.3 | 6.3 | 8.36 | 10.36 | 12.43 |

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 |

| l | Weight (7.85kg/dm3) kg/1000pcs | |||||||||||||

| Nominal | min. | max. | ||||||||||||

| 2.5 | 2.3 | 2.7 | 0.018 | 0.019 | ||||||||||

| 3 | 2.8 | 3.2 | 0.022 | 0.029 | 0.044 | |||||||||

| 4 | 3.76 | 4.24 | 0.029 | 0.037 | 0.059 | 0.1 | 0.13 | |||||||

| 5 | 4.76 | 5.24 | 0.036 | 0.046 | 0.074 | 0.125 | 0.17 | 0.26 | ||||||

| 6 | 5.76 | 6.24 | 0.043 | 0.056 | 0.089 | 0.15 | 0.21 | 0.34 | 0.49 | |||||

| 8 | 7.71 | 8.29 | 0.119 | 0.199 | 0.3 | 0.49 | 0.73 | 1.04 | ||||||

| 10 | 9.71 | 10.29 | 0.148 | 0.249 | 0.4 | 0.68 | 1.04 | 1.39 | 2.5 | |||||

| 12 | 11.65 | 12.35 | 0.83 | 1.28 | 1.74 | 2.98 | 4.42 | |||||||

| 16 | 15.65 | 16.35 | 0.67 | 1.13 | 1.76 | 2.44 | 4.24 | 6.7 | 9.5 | |||||

| 20 | 19.58 | 20.42 | 0.85 | 1.43 | 2.17 | 3.14 | 5.5 | 8.7 | 12 | 20.1 | ||||

| 25 | 24.58 | 25.42 | 2.77 | 4.02 | 7.2 | 11 | 15.3 | 27 | 41.4 | |||||

| 30 | 29.58 | 30.42 | 4.9 | 8.8 | 13.3 | 18.9 | 33.2 | 51 | 70.3 | |||||

| 35 | 34.5 | 35.5 | 5.78 | 10.3 | 15.8 | 22.5 | 39.7 | 61.3 | 83.2 | |||||

| 40 | 39.5 | 40.5 | 11.9 | 18.3 | 26.1 | 46.3 | 71.6 | 98.2 | ||||||

| 45 | 44.5 | 45.5 | 81.9 | 113 | ||||||||||

| 50 | 49.5 | 50.5 | 92.2 | 128 | ||||||||||

| 55 | 54.4 | 55.6 | 145 | |||||||||||

| 60 | 59.4 | 60.6 | 160 | |||||||||||

A DIN 915 socket set screw is a headless screw with an internal hex drive and a dog-point tip, designed to engage with a pre-drilled hole or slot for precise, repeatable positioning without damaging the mating surface.

The dog point provides accurate axial alignment, prevents surface damage, and allows smooth engagement within holes or grooves—ideal for assemblies requiring frequent adjustment or guided linear motion.

DIN 915 screws are typically produced in high-tensile alloy steel (45H or 12.9) for maximum strength, and in A2/A4 stainless steel for corrosion-prone or hygienic environments. Finishes include black oxide and zinc plating.

They are widely used in automation systems, measuring instruments, machine mechanisms, shaft assemblies, indexing devices, and jigs/fixtures where precise positioning and repeatable engagement are crucial.

As an authorized APL dealer, we supply DIN-certified, fully traceable screws, maintain large ready stock, and provide quick pan-India delivery, along with technical support for selecting the correct screw type and grade.