Vimal Industrial Corporation is a trusted stockist and supplier of DIN 315 A Wing Nuts with Rectangular Wings—precision-engineered for tool-free fastening and quick adjustments—based in Mumbai, India. Manufactured to the DIN 315 A standard, these wing nuts feature wide rectangular wings for improved grip, allowing operators to tighten or loosen connections by hand without tools.

Available in stainless steel, carbon steel, and brass, DIN 315 A wing nuts are widely used in assemblies that require frequent disassembly, fine adjustment, or lightweight fastening solutions. Each nut is produced with accurate thread tolerances, robust wing geometry, and consistent surface finishes to ensure reliable performance in diverse industrial and commercial environments.

DIN 315 A specifies wing nuts with rectangular wings and standard metric threads. These nuts are designed to:

Enable manual tightening and loosening without tools.

Provide a large gripping surface for better torque application.

Support quick assembly and disassembly in maintenance-intensive setups.

Function in tight spaces where standard hex nuts are impractical.

Available in multiple property classes for general-purpose and high-strength requirements, as well as stainless grades for chemical, food-grade, and outdoor applications, DIN 315 A wing nuts can be supplied in plain/oiled, zinc-plated, hot-dip galvanized, black oxide, and PTFE-coated finishes to meet varied environmental and service-life demands.

With the growing demand for quick-adjustment fasteners in machinery, fabrication, furniture, and marine industries, DIN 315 A wing nuts are an essential choice for OEMs, MRO workshops, and project contractors.

Vimal Industrial Corporation partners with leading manufacturers, including APL Fasteners, to maintain a ready stock of DIN 315 A wing nuts in various finishes, sizes, and materials. Our Mumbai-based distribution hub ensures same-day dispatch across India, with mill test certificates, lot traceability, and third-party inspection support available on request.

DIN 315 A wing nuts are ideal for installations where manual operation, low-profile fastening, or frequent removal is required.

Common Applications Include:

Machinery & Maintenance

Quick fastening for parts that need regular servicing or calibration.

Furniture Assembly

Tool-free tightening for modular and flat-pack furniture.

Marine & Outdoor Equipment

Stainless steel variants provide corrosion resistance in harsh environments.

Agricultural Implements

Easily removable components on tractors, harvesters, and irrigation setups.

DIY & Hobby Projects

Perfect for prototypes, models, and temporary setups.

As one of India’s most reliable industrial fastener suppliers, Vimal Industrial Corporation delivers quality, speed, and technical expertise to its clients. We supply DIN 315 A Wing Nuts that meet stringent DIN and ISO standards, ensuring consistent fit and performance.

Why clients across India choose us:

✅ Authorized APL Fasteners Dealer – Guaranteed genuine DIN 315 A wing nuts with complete mill documentation.

✅ Extensive Ready Stock – Multiple sizes, materials, and finishes available for immediate dispatch.

✅ Customised Fulfilment – Bulk packaging, bar-coded labels, and site-specific kits available.

✅ Technical Support – Guidance on selecting material, finish, and sizing for specific applications.

✅ Nationwide Logistics – Fast delivery to metros, industrial zones, and remote project sites.

✅ Strict Quality Control – Supplied to DIN 315 A dimensional tolerances with optional third-party inspection.

✅ Customer-First Service – Prompt quotes, dedicated sales support, and export-ready documentation for global shipments.

Whether you’re sourcing for machinery, marine, furniture, or industrial projects, Vimal Industrial Corporation offers a reliable, ready-to-ship solution for all DIN 315 A wing nut requirements.

|

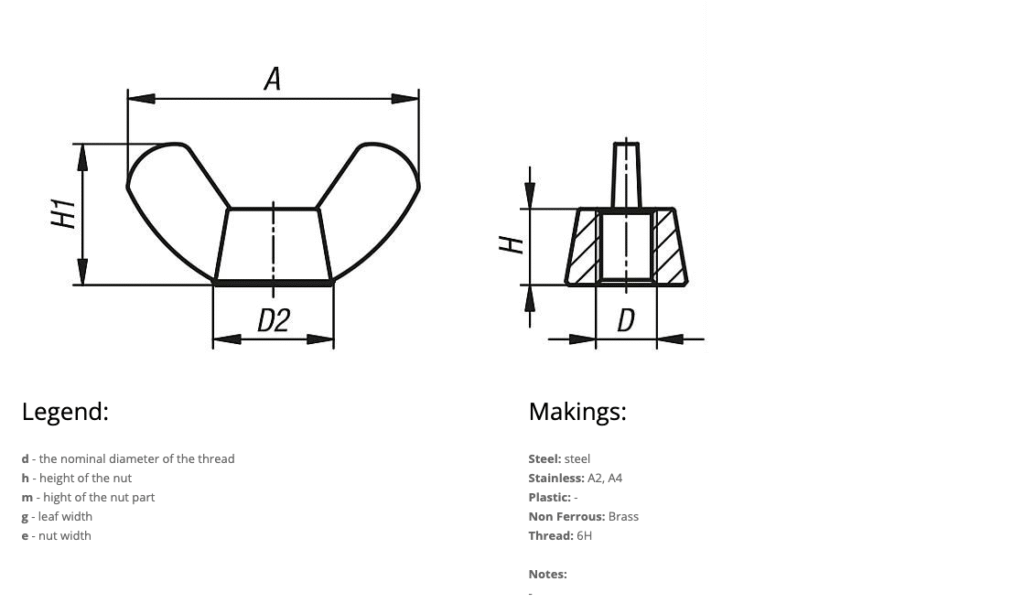

Dimensions of the wing nuts with rectangular petals DIN 315 dimensions in mm |

||||

|---|---|---|---|---|

| d | D | e | h | m |

| M3 | 8 | 17,6 | 8,6 | 2,9 |

| M4 | 8 | 17,6 | 8,6 | 2,9 |

| M5 | 10,3 | 22,5 | 11 | 4,1 |

| M6 | 12,7 | 27,8 | 13,6 | 5,1 |

| M8 | 13,8 | 30,3 | 14,8 | 5,6 |

| M10 | 16,5 | 36,2 | 17,7 | 6,8 |

| M12 | 22,5 | 49,4 | 24,1 | 9 |

| M14 | 26,6 | 58,3 | 28,5 | 10,7 |

| M16 | 26,6 | 58,3 | 28,5 | 10,7 |

| M18 | 29,5 | 68,5 | 33,8 | 13,5 |

| M20 | 29,5 | 68,5 | 33,8 | 13,5 |

The tensile strength depends on the property class and material. For example, stainless steel grades A2-70 and A4-70 have tensile strengths of 700 N/mm², while high-strength alloy steel in property class 12.9 can reach up to 1200 N/mm².

Property Class refers to the mechanical strength rating of a fastener, indicating its tensile strength, yield strength, and hardness. Common classes for wing nuts include 4.8, 5.6, 6.8, 8.8, 10.9, and 12.9.

A2 (304 stainless): General-purpose corrosion resistance, suitable for most outdoor applications.

A4 (316 stainless): Higher corrosion resistance, especially in marine and chemical environments due to molybdenum content.

Hardness values vary by material and property class:

Vickers Hardness: ~130–435 HV

Brinell Hardness: ~124–412 HB

Rockwell Hardness: HR 71–HR 99, or HRC 20–39 depending on class.

Chemical composition determines corrosion resistance, mechanical strength, and suitability for different environments. For example, A4 stainless steel contains higher nickel and molybdenum, enhancing performance in aggressive environments.