DIN 7991 – Socket Head Countersunk Screws Supplier in Mumbai, India | Industrial Fasteners Distributor

Vimal Industrial Corporation is a leading stockist and supplier of DIN 7991 socket head countersunk screws based in Mumbai, India. Manufactured as per DIN 7991 standards, these screws feature a flat countersunk head with internal hexagon drive, combining the flush finish of a countersunk fastener with the high-torque capability of a socket screw. They are ideal wherever components must sit flush or below the surface—such as moving parts, sliding guides, or visually exposed assemblies—without compromising clamping strength.

We maintain a wide inventory of DIN 7991 hex socket countersunk screws in multiple diameters, lengths, material grades, and protective finishes. This allows us to support OEMs, machine builders, automation integrators, fabricators, and MRO teams that require dimensionally accurate, high-performance fasteners for critical joints.

As Indian industry moves toward compact, higher-speed, and aesthetically refined equipment designs, DIN 7991 socket screws remain a key choice for flush-mounted, high-strength joints. Vimal Industrial Corporation works closely with leading manufacturers, including APL Fasteners, to maintain ready stock in sizes typically from M3 up to M24, with standard property classes such as 8.8, 10.9, and 12.9 as well as stainless-steel variants.

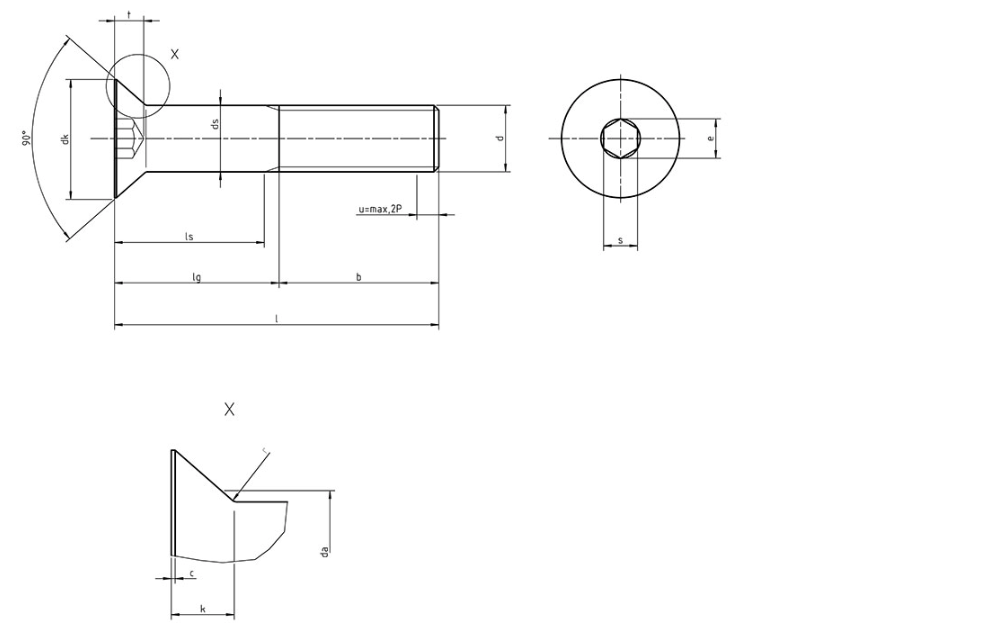

Each batch is produced and inspected in line with DIN 7991 dimensional tolerances—covering head angle, head diameter, drive depth, and thread quality—to ensure consistent torque transfer and reliable engagement with mating components. Screws are stored in climate-controlled warehouses and supplied with mill test certificates, lot traceability, and third-party inspection reports when required. Using our Mumbai hub and pan-India logistics network, we support both urgent shutdown requirements and scheduled project deliveries.

DIN 7991 screws are used where flush surfaces, high strength, and precise alignment are essential:

Machine Building & Automation – linear guides, clamping plates, machine frames, and assemblies where protruding heads would interfere with motion.

Metal Fabrication & Structures – ladders, platforms, covers, and architectural metalwork requiring clean, snag-free surfaces.

Automotive, Rail & Transport – chassis parts, brake components, and interior fittings with flush or concealed fastenings.

Tooling, Dies & Fixtures – precise clamping of plates and components in jigs, fixtures, and mould bases.

Electromechanical Equipment – motor mounts, gearbox flanges, and couplings where tooling access is limited to hex keys.

General Engineering & MRO – retrofit and repair jobs where countersunk socket screws replace conventional slotted or hex bolts for better ergonomics and strength.

With decades of experience in industrial fasteners, Vimal Industrial Corporation is trusted across India for reliable sourcing, technical competence, and on-time supply of DIN 7991 screws.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – assured genuine product with full mechanical and chemical test certification

✅ Broad Stock Range – carbon steel and stainless steel, multiple property classes, diameters, and lengths available ex-stock

✅ Custom & Bulk Packing – project-wise kits, bar-coded cartons, or export-grade pallets as per customer requirement

✅ Technical Support – assistance with strength class selection, countersink geometry, tightening torque, and replacement of existing hardware

✅ Pan-India Distribution – same-day dispatch from Mumbai to major industrial corridors and project locations

✅ Stringent Quality Control – fasteners checked to DIN 7991 tolerances and supplied with lot traceability and inspection reports

✅ Customer-Centric Service – quick quotations, dedicated account managers, and complete export documentation for overseas buyers

Whether you are an OEM, project contractor, or maintenance buyer, we simplify procurement of DIN 7991 socket head countersunk screws with consistent quality, technical clarity, and dependable delivery.

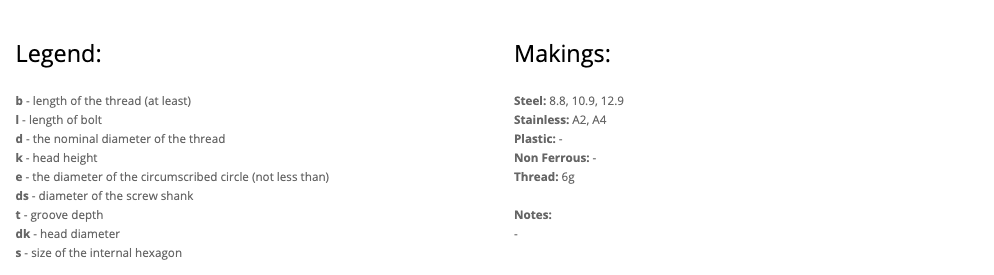

| D | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | 6 | 8 | 10 | 12 | 16 | 4 | 24 | 27 | 30 | 36 | 39 |

| K | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 6.5 | 6.5 | 7 | 7.5 | 8.5 | 14 |

| S | 2 | 2.5 | 3 | 4 | 5 | 8 | 8 | 10 | 10 | 12 | 14 |

| B | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | 54 |

All measurements are in mm

| L (mm) | Weight in kg(s) per 1000 pcs | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | |

| 6 | 0.47 | ||||||||||

| 8 | 0.50 | 0.92 | 1.60 | 2.35 | |||||||

| 10 | 0.56 | 1.07 | 1.85 | 2.70 | 5.47 | ||||||

| 12 | 0.65 | 1.23 | 2.10 | 3.05 | 6.10 | 10.01 | |||||

| 16 | 0.83 | 1.53 | 2.50 | 3.76 | 7.35 | 12.10 | 20.10 | ||||

| 20 | 1.00 | 1.84 | 3.09 | 4.46 | 8.60 | 14.10 | 21.20 | 24.80 | |||

| 25 | 1.35 | 2.23 | 3.71 | 5.48 | 10.20 | 16.60 | 24.80 | 32.10 | 58.4 | 91.4 | |

| 30 | 1.63 | 2.90 | 4.33 | 6.22 | 11.70 | 19.10 | 28.5 | 51.8 | |||

| 35 | 3.40 | 5.43 | 7.10 | 13.30 | 21.50 | 32.1 | 65.1 | 102.0 | |||

| 40 | 3.90 | 6.20 | 8.83 | 14.80 | 24.10 | 35.7 | 71.6 | 111.6 | |||

| 45 | 6.97 | 10.56 | 16.30 | 26.90 | 39.3 | 78.4 | 123.0 | 179 | |||

| 50 | 7.74 | 11.90 | 19.30 | 30.40 | 43.0 | 91.7 | 143.0 | 209 | |||

| 55 | 11.88 | 27.10 | 35.40 | 54.0 | 111.0 | 164.0 | 239 | ||||

| 60 | 34.30 | 41.20 | 62.9 | 127.0 | 200.0 | 289 | |||||

| 70 | 44.70 | 71.8 | 127.0 | 203.0 | 365 | ||||||

| 80 | 52.20 | 80.7 | 143.0 | 226.0 | 299 | ||||||

| 90 | 57.70 | 89.6 | 159.0 | 253.0 | 365 | ||||||

| 100 | < | ||||||||||