Vimal Industrial Corporation is a leading stockist and supplier of DIN 913 socket set screws based in Mumbai, India. Designed according to DIN 913 standards, these screws feature an internal hex (Allen) drive with a flat-point tip, providing a smooth, non-penetrating contact surface ideal for applications requiring secure positioning without damaging the mating shaft or component.

DIN 913 flat-point screws are commonly used where precise adjustment, controlled pressure, and minimal indentation are essential. With a wide inventory covering multiple thread diameters, lengths, and material grades, we support OEMs, automation integrators, machine builders, electrical equipment manufacturers, and MRO teams across India.

Flat-point socket screws under DIN 913 are preferred for repeatable adjustments, frequent repositioning, and clamping onto hardened or delicate surfaces. As an authorized APL Fasteners dealer, Vimal Industrial Corporation maintains ready stock of DIN 913 screws ranging from M3 to M24, available in high-tensile alloy steel (45H, 12.9) and stainless-steel grades (A2/A4).

Each screw is manufactured and tested to conform to DIN point geometry, thread tolerances, hardness requirements, and socket depth accuracy. Products are stored in controlled warehouse environments and supplied with mill test certificates, mechanical reports, and batch traceability. With our Mumbai warehouse and strong pan-India distribution network, we ensure fast dispatch for urgent breakdowns and production requirements.

DIN 913 screws are used where surface-friendly clamping and precise holding are required:

Precision Instruments & Electronics – securing knobs, dials, calibration points, and fine adjustments

Automation & Motion Systems – actuator positioning, linear guides, and alignment blocks

Tooling & Fixtures – jigs, stops, clamps, and adjustable components

Rotating Machinery – non-marring locking of collars, hubs, and couplings

Electrical & Control Panels – terminal locking and mechanical retention

General Engineering & MRO – repair and maintenance tasks requiring gentle yet secure fastening

Vimal Industrial Corporation is trusted for authentic sourcing, fast delivery, and DIN-compliant quality.

Why clients choose us:

✅ Authorized APL Fasteners Dealer – guaranteed genuine, certified products

✅ Extensive Stock – all major diameters, lengths, property classes, and finishes

✅ Custom Packing – labeled boxes, project kits, and export-grade pallets

✅ Technical Assistance – torque guidance, material selection, and point-type recommendations

✅ Nationwide Supply – fast shipment from Mumbai to all industrial regions

✅ Strict Quality Control – hardness, dimensional checks, and traceability documentation

✅ Customer-Friendly Service – prompt quotes, dedicated account managers, and reliable dispatch

Whether for automation, machinery, electronics, or fine mechanical assemblies, we supply DIN 913 flat-point socket set screws that ensure safe, repeatable, and accurate fastening.

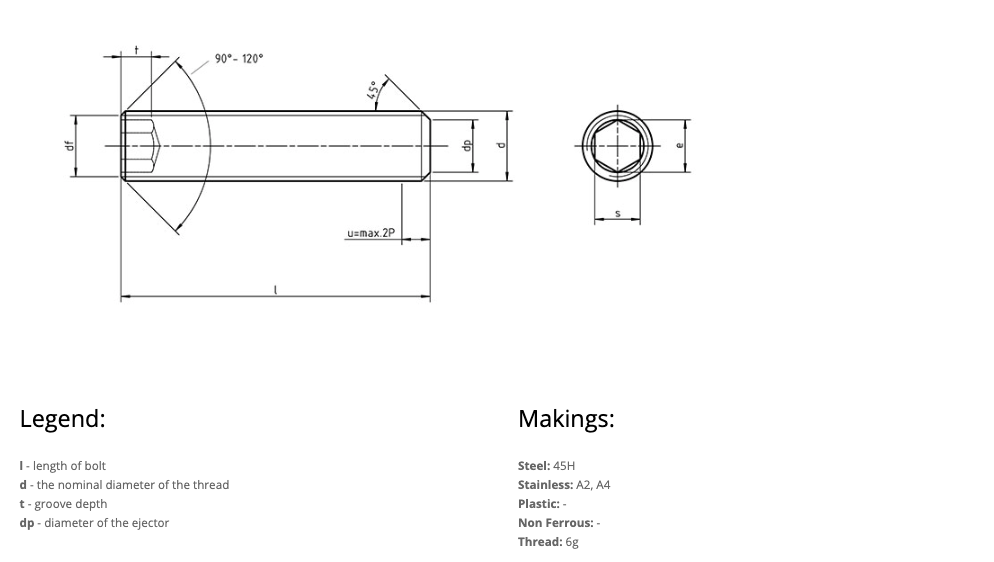

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | |

| df | approx. | Lower limit of minor thread diameter | |||||||||||||

| dp | 0.7 | 0.8 | 1 | 1.5 | 2 | 2.5 | 3.5 | 4 | 5.5 | 7 | 8.5 | 12 | 15 | 18 | |

| min. | 0.45 | 0.55 | 0.75 | 1.25 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 5.2 | 6.64 | 11.57 | 14.57 | 17.57 | |

| e | min. | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 13.72 |

| Nom. | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | |

| s | min. | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 |

| max. | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.08 | 4.095 | 5.095 | 6.095 | 8.115 | 10.115 | 12.142 | |

| t | min. | 0.6 | 0.7 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | 3 | 4 | 4.8 | 6.4 | 8 | 10 |

| min. | 1.4 | 1.5 | 1.7 | 2 | 2 | 2.5 | 3 | 3 | 5 | 6 | 8 | 10 | 12 | 15 | |

| Thread d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | |

| l | Weight (7.85kg/dm3) kg/1000pcs | ||||||||||||||

| Nominal | min. | max. | |||||||||||||

| 2.5 | 2.3 | 2.7 | 0.018 | 0.023 | |||||||||||

| 3 | 2.8 | 3.2 | 0.022 | 0.029 | 0.044 | 0.075 | 0.1 | ||||||||

| 4 | 3.76 | 4.24 | 0.029 | 0.037 | 0.059 | 0.1 | 0.14 | 0.22 | |||||||

| 5 | 4.76 | 5.24 | 0.036 | 0.046 | 0.074 | 0.125 | 0.18 | 0.3 | 0.44 | ||||||

| 6 | 5.76 | 6.24 | 0.043 | 0.056 | 0.089 | 0.15 | 0.22 | 0.38 | 0.56 | 0.76 | |||||

| 8 | 7.71 | 8.29 | 0.119 | 0.199 | 0.31 | 0.53 | 0.8 | 1.11 | 1.89 | ||||||

| 10 | 9.71 | 10.29 | 0.148 | 0.249 | 0.4 | 0.68 | 1.04 | 1.46 | 2.52 | 3.78 | |||||

| 12 | 11.65 | 12.35 | 0.83 | 1.28 | 1.81 | 3.15 | 4.78 | ||||||||

| 16 | 15.65 | 16.35 | 0.67 | 1.13 | 1.76 | 2.51 | 4.41 | 6.78 | 9.6 | ||||||

| 20 | 19.58 | 20.42 | 0.85 | 1.43 | 2.24 | 3.21 | 5.67 | 8.76 | 12.4 | 21.5 | 32.3 | ||||

| 25 | 24.58 | 25.42 | 2.84 | 4.09 | 7.26 | 11.2 | 16 | 28 | 42.6 | 57 | |||||

| 30 | 29.58 | 30.42 | 4.97 | 8.85 | 13.7 | 19.6 | 34.6 | 52.9 | 72 | ||||||

| 35 | 34.5 | 35.5 | 5.85 | 10.4 | 16.2 | 23.2 | 41.1 | 63.2 | 87 | ||||||

| 40 | 39.5 | 40.5 | 12 | 18.7 | 26.8 | 47.7 | 73.5 | 102 | |||||||

| 45 | 44.5 | 45.5 | 83.8 | 117 | |||||||||||

| 50 | 49.5 | 50.5 | 94.1 | 132 | |||||||||||

| 55 | 54.4 | 55.6 | 147 | ||||||||||||

| 60 | 59.4 | 60.6 | 162 | ||||||||||||

DIN 913 defines a headless socket set screw with an internal hex drive and flat-point tip, used for controlled clamping where no surface damage or indentation is desired.

DIN 913 has a flat point for non-marring, smooth contact.

DIN 916 has a cup point that bites into the material for maximum holding force.

DIN 913 is ideal for adjustments; DIN 916 is ideal for rotational locking.

They are commonly available in hardened alloy steel (45H/12.9) for strength and stainless steel A2/A4 for corrosion-resistant applications such as food, chemical, or outdoor environments.

They are used in precision equipment, instrumentation, tool fixtures, actuator alignment, and machine assemblies requiring secure positioning without damaging the mating surface.

We offer DIN-certified, traceable screws, maintain large ready stock, and ensure same-day dispatch, backed by technical guidance and complete QA documentation.